Enwere ọtụtụ ụzọ maka ịgbado ọkụ igwe, dị ka ịgbado ọkụ argon arc ọdịnala, ịgbado ọkụ eletrik na igwe ịgbado ọkụ nkịtị ndị ọzọ.

N'ime afọ ole na ole gara aga, ịcha laser na ịgbado ọkụ laser abanyela n'ọhịa nhazi na nhazi ígwè.The elu arụmọrụ na mma nkeigwe ịgbado ọkụ laser ejiri akabụ ihe doro anya, na "mmetụta ịgbado ọkụ iteration ígwè" ngwa ngwa na-emepụta, nke nwere ike fọrọ nke nta dochie argon arc ịgbado ọkụ, eletriki ịgbado ọkụ na ndị ọzọ usoro.Enwere ike iji ya na ngwa ngwa ọnụ ụzọ na windo, ọrụ aka, ọkụ, mgbasa ozi igwe, kichin na ụlọ ịsa ahụ, tebụl, ngwa kichin, igwe ọrụ ugbo na ọhịa, ngwa ahụike, ngwa egwuregwu egwuregwu, igwe ihe owuwu na ụlọ ọrụ ndị ọzọ.

1. Knoppo Laser na-enye ngwọta ngwakọta nke ịkpụ ígwè, ịgbado ígwè na ịgbado ígwè.Ọmụmaatụ ,eriri laser ịgbado ọkụ igwe , Igwe na-ehulata CNCna eriri laser ịgbado ọkụ igwe, na nwere ike inyere ndị ahịa na-emepụta mara mma ngwaahịa.

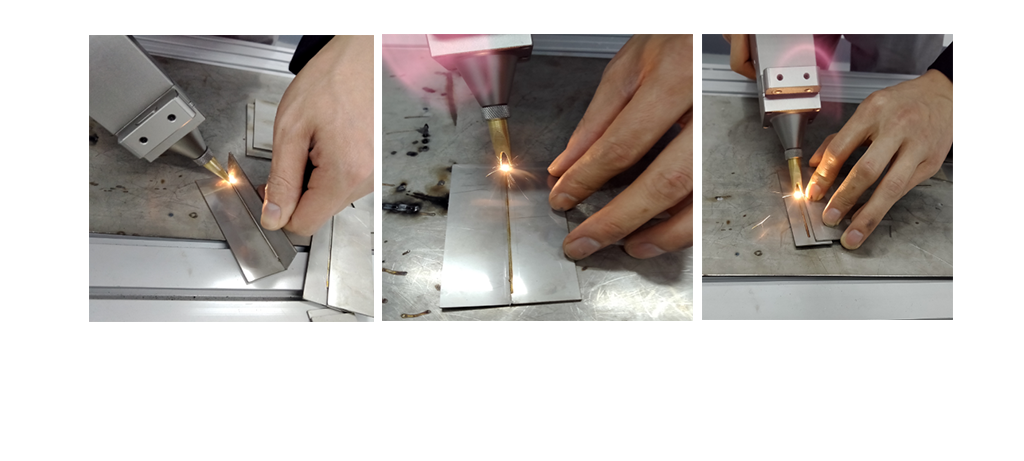

2.The aka-ejide laser welder mma ịgbado ọkụ ntụpọ dị ka undercut, ezughị ezu penetration, ok pores na cracks na-eme na omenala ịgbado ọkụ usoro.The welded seam mgbe ịgbado ọkụ bụ ezigbo na mara mma, nke na-ebelata ụdi egweri usoro na-azọpụta oge na ego.Na e nwere ole na ole consumables, ogologo ndụ, na ọ pụrụ ịbụ flexibly adabara dị iche iche gburugburu.

1).Naanị tọọ parampat ma ị nwere ike ibido ozugbo.Mgbe dochie nozulu, ọ dị mfe ime ewepụghị ịgbado ọkụ, esịtidem akụkụ, mpụga akụkụ, overlap welding, wdg.

2).Oghere laser bụ otu, ịdị mma dị elu, na-aga n'ihu ma kwụsie ike, na nke enweghị ọkụ.Mmetụta ịgbado ọkụ bụ otu ma ị bụ onye novice ma ọ bụ aka nka.3. A gaghị enwe nsogbu dị ka pores, weld bead, weld penetration, and workpiece deformation.

3).N'ihi na metal ihe dị ka igwe anaghị agba nchara, galvanized mpempe akwụkwọ, oyi efere, wdg, ọ nwere ike ihu ọma na-aghọta otu oge ngwa ngwa ịgbado ọkụ, nke bụ ọtụtụ ugboro ngwa ngwa karịa ndị ọzọ ịgbado ọkụ ụzọ.

3.Igwe ịgbado ọkụ Laser Handheld Knoppobụ ngwa ọhụrụ na-anọchi anya ịgbado ọkụ ọdịnala.Ọ nwere ọsọ ịgbado ọkụ ngwa ngwa, nke dị ihe dị ka ugboro 5-10 ngwa ngwa karịa ịgbado ọkụ ọdịnala.Ngwá ọrụ dị mfe iji rụọ ọrụ, yana arụmọrụ ịgbado ọkụ dị elu.Otu igwe nwere ike ịchekwa ma ọ dịkarịa ala 2 welders kwa afọ, na laser nwere ogologo ndụ ọrụ (karịa 100,000 awa).Nwere ike belata ọnụ ahịa akụrụngwa yana ọnụ ahịa ọrụ.

4. Uru nke Knoppo eriri laser ịgbado ọkụ igwe:

1).Dị mfe, dị mfe ịmụta, mgbanwe na adaba.Ịkwado usoro ihe eji eme ihe, onye na-arụ ọrụ anaghị achọ, a pụrụ iji ọzụzụ dị mfe mee ihe, ọrụ dị mfe, ngwa ngwa ịmalite;Multi-akụkụ ịgbado ọkụ, mgbanwe na adaba;

2).Ọnụ ntinye dị ala na ọnụ ahịa mmezi.Ịgbado ọkụ laser ejiri aka, ọ dịghị mkpa maka tebụl ịgbado ọkụ dị mma, obere ihe oriri, ntinye ngwá ọrụ dị ala na ụgwọ ọrụ na-akwụ ụgwọ, yana ọnụ ahịa dị elu;

3).Chekwaa ọrụ.Ịgbado ọkụ laser ejiri aka na-adị ngwa ngwa, ugboro 5-10 ngwa ngwa karịa ịgbado ọkụ ọdịnala, otu igwe nwere ike ịchekwa ma ọ dịkarịa ala 2 welders otu afọ;eriri weld mgbe ịgbado ọkụ na-adị mma ma mara mma, na-ebelata usoro polishing na-esote, na-azọpụta oge na ọnụ ahịa;

4).Ogo dị mma.The laser ịgbado ọkụ workpiece enweghị nrụrụ, ọ dịghị ịgbado ọkụ scar, na ịgbado ọkụ bụ ike;

5).Nchedo nchekwa.Ọ nwere ọrụ nchekwa nchekwa ụdị kọntaktị iji zere mgbapụta ọkụ na mberede ma hụ na enwere ike ịgbanye ọkụ naanị mgbe emechara ya na igwe.Ejiri enyo nchebe laser, nke a ga-eyi mgbe ị na-agbado ọkụ.Iji hụ na nchekwa.

Oge nzipu: Dec-15-2021